Application : For tension-controlled winding of wire on vertically mounted bobbin in synchronization with enamelling or coating line.

Take up is offered to suit the wire diameter, Material, Diameter range of Bobbin to be loaded and the Maximum Line speed.

We offer custom coilers to suit customer requirements – Diameter range and weight of bobbin, Rod diameter, Flat size and Speed.

Bobbin Dimension : As per Customer requirement

Bobbin Weight :

As per customer requirements

Bobbin Loading : Shaft type with pintle. Bobbin is loaded vertically on the bobbin shaft with drive plate, pintle on bottom side and pintle and lock nut on top side. For unloading bobbin shaft is removed with handle. Pintles supplied will be suitable to bore dimensions.

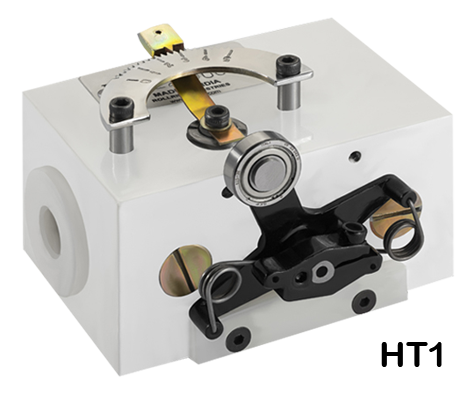

Traverse Assembly : Vertical traverse assembly with Rollring traverse unit. Bobbin speed is synchronized with traverse speed. Traverse pitch and stroke length are finely adjustable. Guide pulley assembly mounted on a carrier with linear bearings and guide shaft.

Drive : AC geared motor with variable frequency drive. AC Motor will be operated in torque mode. Tension and speed is very finely adjusted with potentiometer.

Alternatively, Torque motor is offered with dimmer stat. Winding tension and speed can be finely adjusted by varying the voltage applied to torque motor with the dimmer stat.

Control Panel : Provided