Application : To rewind steel or aluminium wire or strip from large coil to small coil.

Number of winding heads per line : Single or Dual head

Machine construction : The machine will be of fabricated construction with single or dual winding heads.

Dual head coiler : Two number winding head will be mounted side by side for quick change over of the wire from first bobbin to second bobbin. The Coiler consists of a collapsible former mounted on head stock and tail stock, Traverse assembly, Motor, and Control Panel. Single motor and Traverse assembly operate for both the winding heads. Electromagnetic clutch provided.

Collapsible former : Barrel segments will collapse when the tail stock is operated and coil can be easily removed after tying. Pneumatically operated tail stock is provided. Slots are provided on the flanges for tying the coil manually.

Flange diameter : 125mm

Width : 50mm

Barrel diameter : 50mm diameter or 45 mm Square.

Winding speed : Winding speed

Material : MS/HC Wire or Aluminium

Wire size : 0.7mm to 2mm

Strip size : 2mm width x 0.5mm

Coil Weight : 1.7 Kg

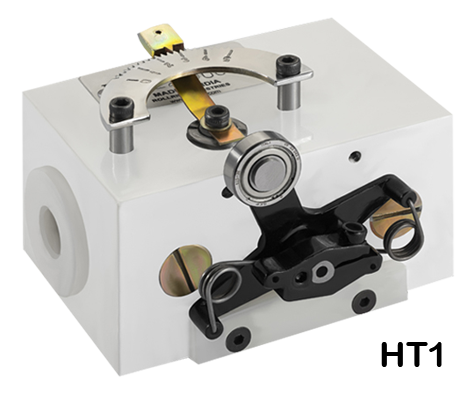

Traverse Assembly :With Rollring Traverse unit . Winding pitch and stroke length can be finely adjusted. Guide assembly with adjustable grooved rollers and guide pulley is provided.

\Drive : 1 hp AC geared motor 3 phase 415 volts. AC variable frequency drive can be offered for speed control.

Drive Transmission : VBelt

Control Panel : Control panel with AC Variable frequency drive and accessories are supplied

Pay off stand(optional) : Payoff for unwinding large coil is also offered as per requirement.

Application : For tension controlled Unwinding of steel wire in coil Vertical Swift type pay off can be offered to suit the dimension of coil.

Brake : Disc brake

Tension Control : Disc brake. Tension adjustable with knob or Air pressure regulator