Application : For tension controlled rewinding of cable, conductors or ropes. We offer rewinding line to suit customer requirements

Bobbin Dimensions :As per Customer requirement

Maximum Flange Diameter : 2500mm

Maximum Filled Weight : Poly Propylene

Rewinding line consists of Pay off, Take up, Traverse assembly and control panel.

Bobbin Loading : On Pintles. Pintle shaft assembly mounted on two number vertical column. The column movement is motorized and movable in X-axis on column bed and the pintle housing moveson Y-axis on the column. AC geared motor with torque limiter is provided for column and Pintle movement. Pintle shaft is assembled on a sturdy housing with heavy duty bearings. Pintle to suit bobbin bore are supplied.

Loading/Unloading : Bobbin can be easily loaded or unloaded from floor level. Drum lifting and lowering as well pintle movement is motorized

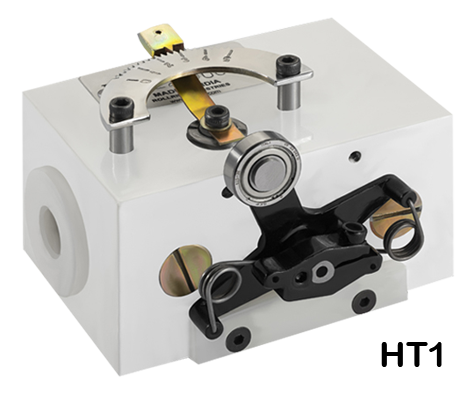

Payoff Tension Control Disc brake. Air pressure regulator provided for controlling the tension.

Pay off Brake : Disc brake

Take up Drive : By AC motor with variable frequency drive. Encoder provided to maintain line speed.

Traverse Assembly : With Rollring Traverse unit. Traverse Pitch and Traverse length is finely adjustable. Guide assembly is mounted on a carriage with linear bearings and guide shaft /rail

Traverse Drive : By AC geared motor

Traverse assembly with Ball Screw and Servo motor can also be offered. Ball screw assembly with servomotor, servo drive, HMI, PLC , Encoder etc. areprovided for layer winding. Traverse pitch is very accurately controlled. Winding sequence can be programmed in the HMI.

Length Counter : Electronic

Brake : Disc brake