Application : Tension controlled coiling Aluminium / aluminium alloy wire in synchronisation with the extruder press in to coils. Coiler is also offered for Rewinding. Coiler will be suitable for diameter of wire up to 15mm. Adjustable former is provided for easy unloading of coils after winding. Pressure roller is provided to hold the wire before cutting and it will be safe to handle the product without loosening of coil.

We offer the coiler to suit customer requirements

Machine construction : Coiler consists of a Tension controlled winder with adjustable former, Traverse assembly, Motor with reduction gear box, Control panel with AC variable frequency drive etc.

Machine will be of fabricated construction of robust design with adjustable former, Traverse assembly, motor and reduction gearbox, operating desk etc. assembled on a heavy duty gearbox.

Centre height : 1250mm

Max wire diameter : 15mm

Material : Aluminium or Aluminium Alloy

Weight of Coil : Customer specified

Coil Inside diameter : Customer specified

Max Coil Outside diameter : Customer specified

Max Coil Length :Customer specified

Max Line Speed : Customer specified

Former : Coil is wound on an adjustable former, diameter of which can be finely adjusted with a handle. Add on segments can be provided to increase the diameter range. Former will be sturdy design and consists of four MS segments. Flange with four slots is mounted on the Shaft. Suitable slots provided for tying the coil at four points before unloading.

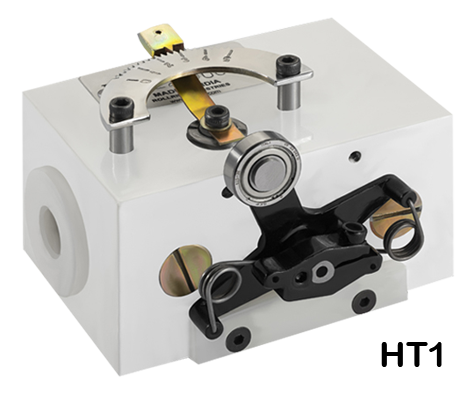

Traverse Assembly : Rollring Traverse unit is provided. Traverse pitch and Traverse Length can be finely adjusted. Guide roller assembly is mounted on a carrier with linear bearing and two number shaft. Traverse speed is automatically synchronised with coiler speed.

Guide roller assembly : Guide roller assembly consists of a Tensioning roller assembly with 2 horizontal rollers in which the top roller is adjustable with a handle and 2 sets of Vertical rollers and two sets of horizontal grooved roller.

Guide roller assembly is mounted on a carrier with four linear bearing and two number guide shaft.

Drive : With AC Motor with reduction gear box. The Motor will be operated in Torque mode for automatic speed synchronisation.

Drive Transmission : V-Belt / Chain Drive

Tension and Speed Control : The winding tension and speed is very finely adjusted with potentiometer on the operating desk for compact winding. Line speed is controlled by Press speed and speed reference is taken from press PLC.

Control panel : Control panel with ABB, Siemens or any reputed make AC Variable frequency drive, MCCB, Control transformer, MCB and accessories are provided. Each coiler has an independent AC VFD and controls.

Operating desk :Operating> With push button and Potentiometer mounted on each coiler.

https://www.youtube.com/watch?v=K5EwffYtsHw