Application : Tension controlled winding of steel strip from a single steel coil to a jumbo coil.

Recoiler consists of Vertical Pay Off / Unwinder for loading the single steel coil and awinder with adjustable former.

We offer custom Rewinding Line to your requirements:- Dimensions and Weight of single, Finished Coil dimension, Maximum Coil weight and Maximum Line speed.

Dimension of a Single coil : As per customer requirement

Maximum Coil Width : 25mm

Thickness : 0.2mm to 1.2mm

Coil OD : As per customer requirement

Finished Coil Dimension

Inside diameter of Coil : 300mm and 400mm. Card board core of 300mm and 400mm can be loaded on the adjustable former.

Maximum Coil width : 500mm

Maximum Coil weight : 2000 Kg

Maximum Coil Outside Diameter : 1250mm

Machine Construction : Machine is of fabricated construction of robust design. Head stock housing with adjustable former, traverse assembly, drive motor etc. are mounted on a common base frame.

Head stock Gear Box : Shaft with former is assembled on heavy duty bearings with oil lubrication. Gear box will be of sturdy design.

Adjustable Former : Coil is wound on an adjustable former suitable for loading 300mm and 400mm inside diameter Core. Former will be of robust design to carry a maximum coil weight of 2000Kg. Diameter of former can be increased or decreased with a handle. The segments are collapsed with handle to remove the coil with card board core easily after strapping. Add on segments are supplied for loading the 400mm ID core which are bolted on bottom segment. We can supply suitable Former of different diameter range as required.

Maximum Winding speed : 200 Meters/Minute

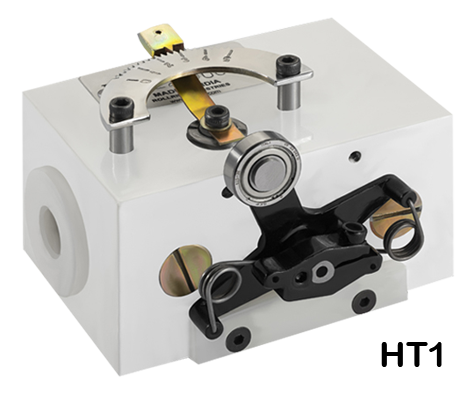

Traverse Assembly :Traverse assembly with 191825Rollring Traverse unit is provided. Traverse Pitch and traverse length can be adjusted as required. Strip guide assembly is mounted on a carrier with 4 linear bearings and 2 guide shafts. Linear speed is automatically synchronized with coiler speed.

Strip Guide Assembly : Guide assembly consists of a tensioning roller assembly with adjustable rollers, a guide arm with rollers to guide the strip, pressure pad etc. A swivelling type Guide arm is supported on a carrier with linear bearing for X-axis movement is provided. The position of the guide arm can be finely adjusted in Y-axis with a hydraulic cylinder and hand lever pump during winding as required.

Length counter : Electronic

Drive : AC Motor with Reduction gear box

Speed Control : By AC variable frequency drive

Control Panel : Control panel with ABB, Siemens or any reputed make AC Variable frequency drive and its accessories

Operating Desk : Operating panel with push button, lamps and a potentiometer

Brake : Disc brake

Pay-Off (Unwinder)

A Vertical pay off provided for tension-controlled unwinding of a single coil. Coil is loaded on the vertically mounted adjustable former and a base plate. The diameter of former can be adjusted very finely for holding the single coiltight. Former is suitable for loading of coil with inside dia 300mm and 400mm.

Single Coil Dimension :

Inside diameter : 300mm and 400mm

Maximum Outside Diameter : 1000mm

Width : 25mm (Maximum)

Tension control : Disc brake with Precision air pressure regulator

Brake : Disc brake

Optional We can offer hydraulically operated tilting arrangement of the stand for loading the coil horizontally.