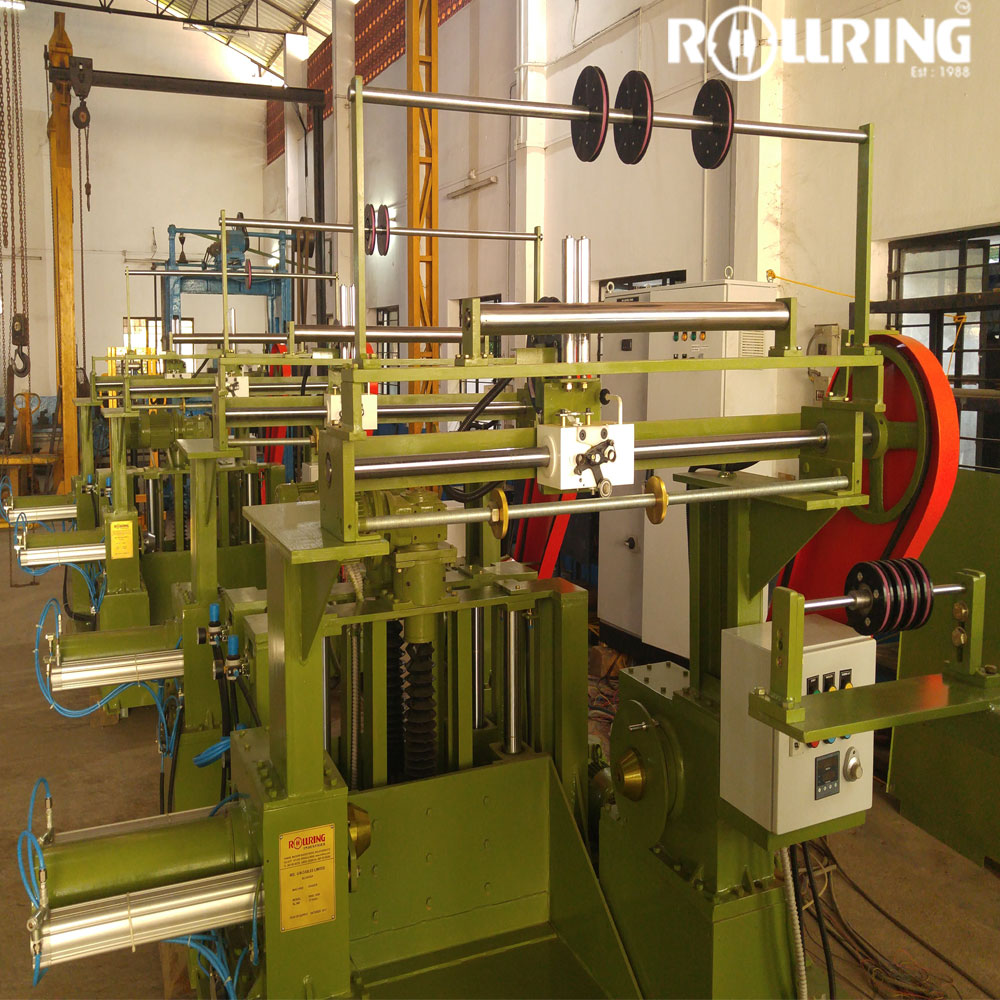

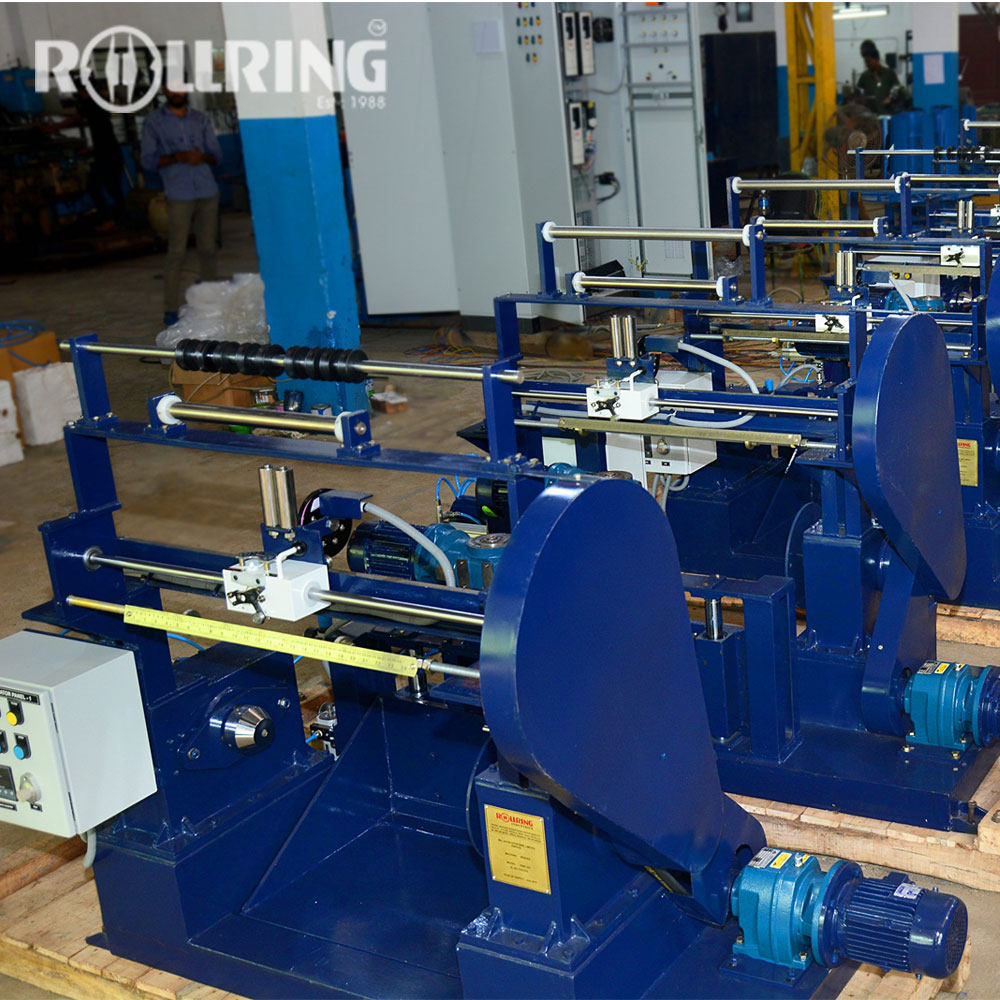

Application :Tension controlled winding of wire from UV line on multiple winding heads with capstan for pulling the wire through the UV system. Take will be mounted one behind the other in one line. Suitable floor space Can provided between two set of take up for loading and unloading bobbin.

We offer Winder with capstan assembly to suit customer requirements Dimensions and weight of bobbins to be used, Wire size and maximum line speed.

Number of Winder per line : As required. Maximum 10 number Bobbin Dimensions and weight : As per customer requirements.

Maximum Flange Diameter : 1200mm

Maximum Weight : 900 Kg

Wire diameter : 0.4mm to 4mm

Maximum Line speed : Meters/Minute. Variable speed.

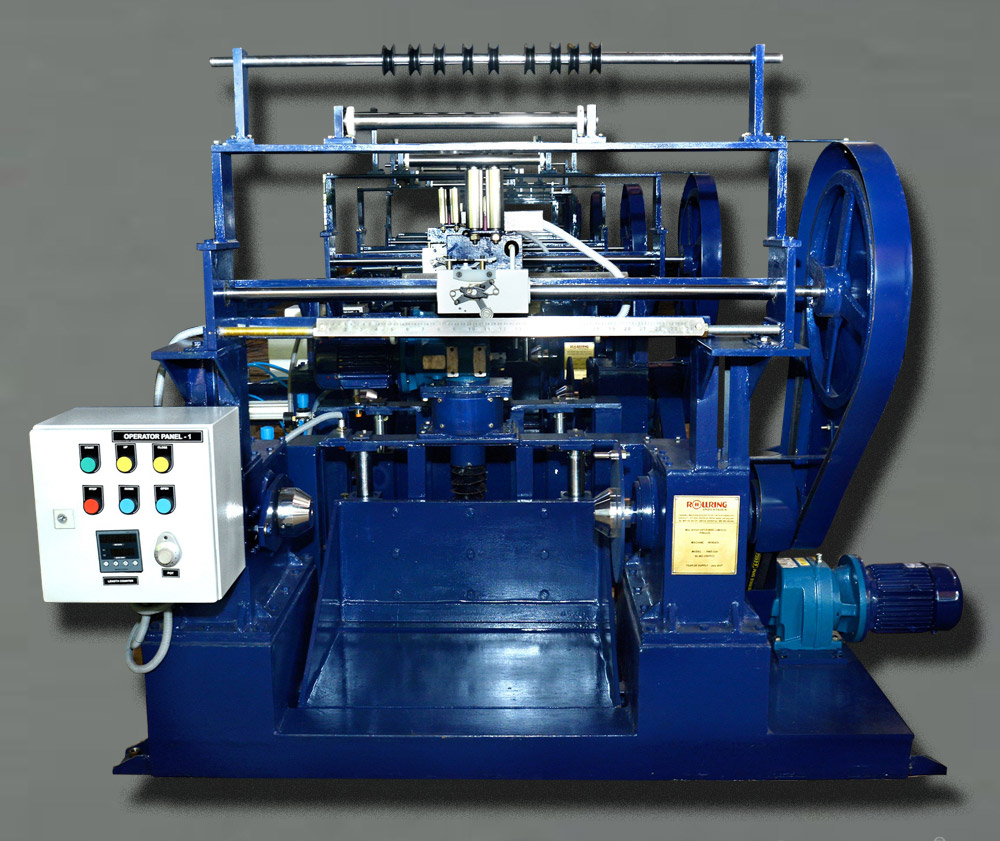

Bobbin loading : Pintle type between ahead stock and a tail stock.

Head Stock : Head stock shaft with pintle and dive pulleys are assembled on a sturdy housing with heavy duty bearings.

Tail stock : Tail stock shaft with pintle is assembled on a sturdy housing with heavy duty bearings. We offer pneumatically operated or screw operated tail stock

Loading and Unloading of Bobbin : Motorized with AC geared motor.

Drive : With AC motor with reduction gear box.

Drive Transmission : V Belt

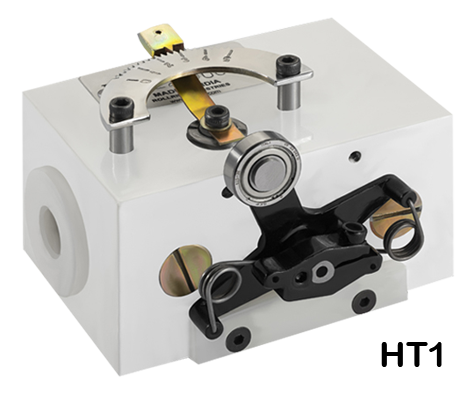

Traverse Assembly : With of Rollring Traverse unit. Traverse Pitch and stroke length can be finely adjusted. Traverse speed is automatically synchronized with bobbin speed. Guide carrier with 4 linear bearings and 2 guide shafts are provided for mounting ceramic wire guide pulley. Suitable guides with ceramic pulleys are provided on top of traverse assembly to guide wires to different bobbin.

Length Counter : Electronic

Non-driven payoff : Disc brake with precision air pressure regulator.

Speed and tension Control : With AC variable frequency drive. Tension can be very finely adjusted with potentiometer. AC motor is operated in torque mode. Take up is synchronized with capstan speed

Drive Transmission : VBelt

Operating desk : Provided for each take up

Safety Guards and Covers : Safety covers provided for all drives.

Sliding door on the front side offered on request.

Pneumatic components : All pneumatic components will be of Festo Make.

Brake : Dynamic braking with DBR

Capstan assembly

Capstan assembly provided for pulling the wire through the UV system.

Number of Capstan : Two. Both capstan will be driven by a common drive.

Capstan diameter : 520 mm

Number of Groove : As required depending on the number of line

Centre Height : 1000 mm

Drive : By AC Motor with Reduction gear box

Drive Transmission : Chain Drive

Line Speed : 200 meters per minute Maximum. Line speed is varied by varying the capstan speed with AC Variable frequency drive. Line speed displayed.

Control Panel : Control Panel with ABB, Siemens or reputed make AC variable frequency drive with accessories are supplied. Individual AC Drive provided for Capstan and each winder. Capstan motor is operated in speed mode and winder motors are operated in torque mode.