Application :For automatic Layer winding of Insulated Wire or Rectangular conductor on mandrel as per design parameters programmed in the HMI

We supply layer winding machine to suit your requirements of dimensions of coil to be manufactured, diameter of Wire and size of Rectangular conductor. Accessories available Adjustable former, Tensioning stand for wire, De realer loading number of bobbins, Edge strip holder, Paper roller stand.

Wire diameter : 0.3mm to 6mm (Maximum)

Rectangular conductor : 70mm2 (Maximum)

Material : Copper or Aluminium

Coil height : 1500mm (Maximum)

Coil outside diameter : 1000mm (maximum)/p>

Coil Inside Diameter : To suit your requirements

Coil Weight : 2000Kg (Maximum)

Shape of coil : Concentric circular

Head Stock : Consists of heavy duty Gear box of robust design. Shaft mounted on heavy duty bearings and provided with face plate for loading the mandrel.

Mandrel Shaft : we can supply shaft for loading the wooden former or adjustable former. Shaft or Mandrel is bolted to face plate of head stock shaft and supported with tail stock pintle. Drive plate and threaded nut provided on the shaft for loading wooden former.

Tail Stock : Tail stock assembly is mounted on a swivelling arm or on a pedestal movable with handle. Tail stock pintle movement with handle with locking arrangement.

Unloading of finished Coil : Coil is removed easily with crane after opening tail stock.

Drive : With AC Motor and Reduction gear box.

Drive Transmission : Timer belt Or Duplex chain

Mandrel Speed : 400 RPM (Maximum).

Foot Switch : Machine operated with foot switch. Separate foot switch provided for Forward and Reverse operation

Brake : Disc brake

Traverse Assembly : Ball screw operated by Servo motor provided for Layer Winding. Traverse movement is very accurately controlled with reference to program stored in the HMI. Layer winding as per the design specifications is controlled by the PLC and servo drive.

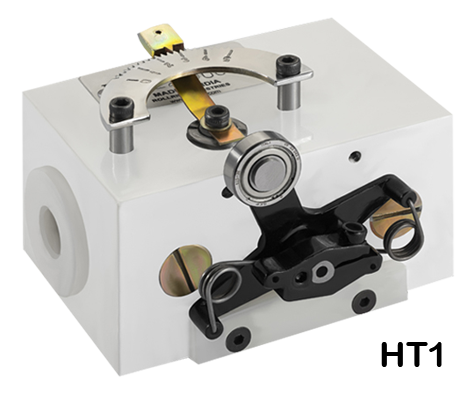

Guide Carriage : Guide Carriage with LM block and Rail mounted on a machined plate provided . Wire guide pulley assembly or tensioning roller assembly are mounted on the carriage. Carriage will be moving and supporting the Wire or Rectangular conductor with its guides along the length of machine.

Separate guide assembly is provided for wire and Rectangular conductor which can be easily interchanged.

Tensioning roller assembly : Tensioning roller assembly is provided for guiding the rectangular conductor. Will be suitable to guide required number of conductor to be layer wound. Consists of six number horizontal rollers suitably assembled. Top rollers are adjustable with handle for tightening the conductor. Alternatively Air cylinder with pressure regulator can be provided (optional).

Guide assembly for wire : Consists of four number pulleys, one number pulley pneumatically broken, and one pulley mounted on adjustable arm to guide the wire near to mandrel.

Control Panel : Control panel with Siemens make AC variable frequency drive, Servo drive, PLC, HMI, Encoder , and accessories are supplied. Operating desk with HMI is suitably mounted on a swivelling arm ,easily accessible to operator. HMI : Program can be created and stored in the HMI. HMI will display all winding parameters and status of the winding.

Several Winding program like - Left or right side start, starting point, Number turns per layer, total number of turns, Diameter of wire, width of conductor, Pitch, Coil length, Number of turns for Tapping, Slow down number of turn can programed and stored in the HMI. Program can be recalled as required by the operator.

Optional Accessories

1)Mandrel : We can supply mandrel to suit minimum and maximum dimension of coil to be manufactured.

Diameter of mandrel is manually adjustable with handle and can be locked after adjustment. Eight numbers of wooden segments are mounted on the mandrel with multiple radial and axial supports. Wooden segments will be polished and will be made of hard wood. Mandrel diameter range as required can be offered. Maximum Length of segments 2000mm.

Number of Segment : Eight

Expansion Range : Expansion in each stage varies from 40 mm to 100mm depending on size of mandrel pipe. Add on segments are supplied to increase the diameter range.

Maximum Coil weight : 2000Kg

2)Tensioning stand : for Wire with pneumatically controlled tensioning arm

3)De realer (Bobbin Stand) : De realer provided for loading required number of bobbin with rectangular conductor . Bobbins are loaded on a frame mounted with trolley wheels. Two number rail provided for movement of frame carrying the bobbin parallel to mandrel . Trolley movement is motorized with AC geared motor and can be operated with push button on operating desk.

Drive : AC geared motor. Proximity sensor provided at end limits

Number of Bobbin : 48 (Maximum)

Bobbin loading : Shaft type

Full width insulation de-coiler (Paper / DDP)

De Realer for edge strip