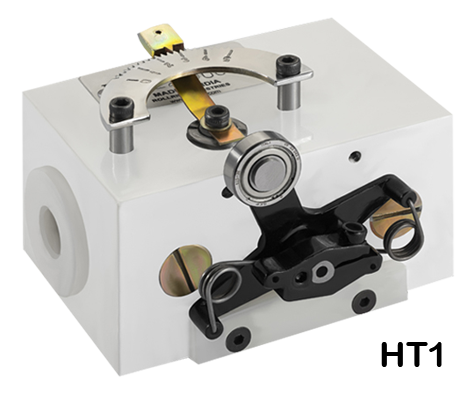

Optional Accessories

Free Movement Lever (Release Lever)

Designed to meet customer requirements, this lever facilitates the disengagement of the traverse unit from the shaft. By manually rotating the lever 90 degrees, you can easily disengage and reposition the traverse unit.

Types of Release Levers

Type FM1 : Positioned on the bottom side. Compatible with all models except the HT1.

Types of Release Levers

Type FM2 : Positioned on the top side. Available exclusively for the three rolling ring models.

Shaft

Shafts are induction hardened and ground with hard chrome plating, available up to a length of 4000 mm. Custom end machining, circlip grooves, and keyways can be provided based on customer requirements.

Pneumatically Operated Reversal Mechanism

This mechanism facilitates both clockwise and counterclockwise operation of the traverse unit without requiring modifications. It includes an air cylinder with a solenoid valve, actuated by proximity sensors at the end limits.

Bi-directional Reversal Mechanism

Designed for applications requiring both clockwise and counterclockwise shaft rotation.

Remote Control of Linear Speed

A small motor integrated into the traverse unit allows for remote adjustment of the linear speed.

Download Catalogue