We are manufacture and exporters of Traverse Unit, Traverse assembly, Linear drives, Spooling Machine, Take up, Rewinding Lines, Winder for FRP line, Layer and Cross Over Winding machines for Transformer, Strip Winding and Vertical Take up.

- Your Trusted Partner in Traverse Units, Assemblies, and Linear Drives

Our Product Range

We are involved as the manufacturer and exporter of an exclusive range of Winding Machine, Take Up Machine, Traverse Unit, Stainless Steel Strip and many more. We also render Winding Machine Repairing Service and Spooling Machine Repairing Service.

Rollring Industries

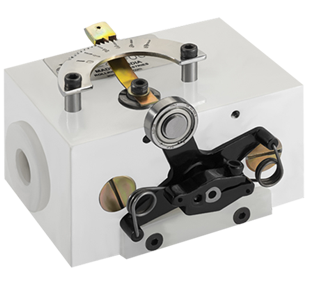

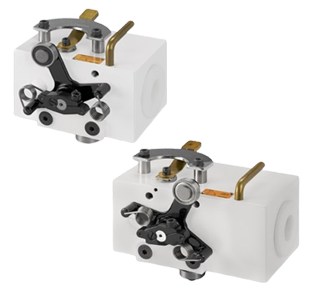

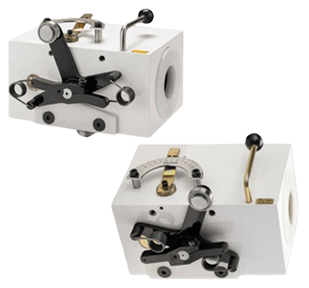

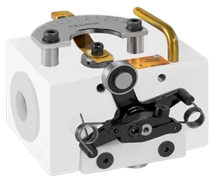

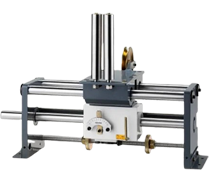

Traverse Unit

Leveraging the skills of our qualified team of professionals, we are instrumental in manufacturing and exporting a wide range of Traverse Unit. This Traverse Unit is quality approved.

Rollring Industries

Linear Drive Nut

Prominent & Leading Manufacturer from Kozhikode, we offer rrld16 linear drive nut, rrld15 linear drive nut, rrld30 linear drive nut, rrld 25 linear drive nut, rrld 20 linear drive nut and linear drive nut.

Rollring Industries

Machines

Spooling Machine, Rewinding Machine, Pay off Stand, Swift type pay off, Rewinding Machine for CO2 wire, Coiling machine for small coil, Recoiler for Stainless steel strip etc...