India’s Largest Exhibition for Wire & Cable Industry

6th International Exhibition & Conference for Wire & Cable Industry

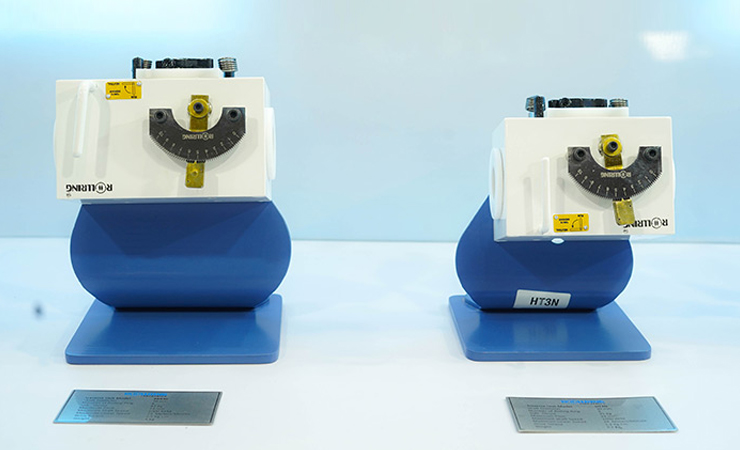

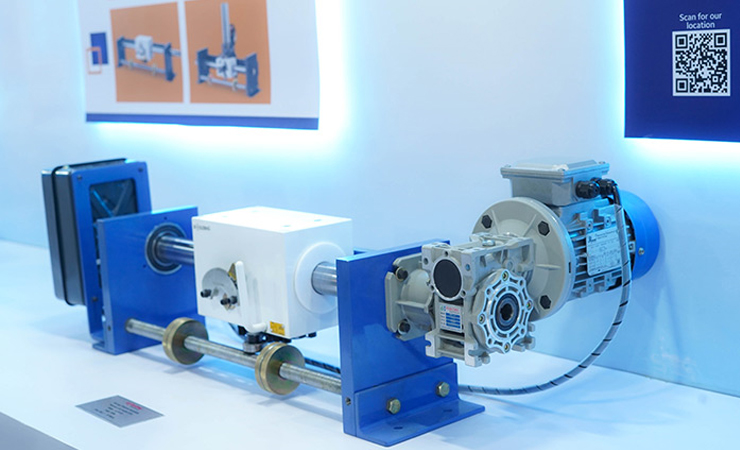

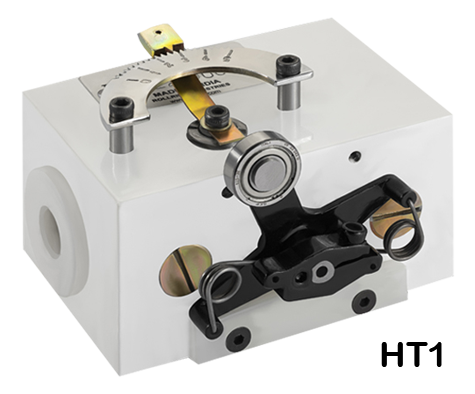

We are Honored to Welcome, Rollring Industries at Cable & Wire Fair 𝟐𝟎𝟐𝟓.

4-6 Nov 2025 | Pragati Maidan, New Delhi

For more info, visit https://www.cablewirefair.com/.

Booking inquiries, reach out at +91 99999-35011 | info@wirecable.in

Cable & Wire Fair is the largest convergence of wire and cable industry in India centred at creating a consensus driven, growth-oriented stage for the industry. The exhibition cum conference – spanning 3 days, is organised by Tulip 3P Media Private Limited, bi-annually at Pragati Maidan, New Delhi, India. On one hand- exhibitors from all over the world put their products, machineries, and technology on display and on the parallel side- the conference showcases high-voltage discussions at its cable conclaves and technical session wherein a myriad of issues pertaining to the wire and cable industry are considered. This is the real global stage where you can feel the actual pulse of the industry and be a part of the industry’s growth story. Inaugurated in 2015, Cable & Wire Fair has grown 12x times since its launch! Tube & Pipe Fair was launched as a colocated show in 2023 and in 2025, Bharat Metal Expo will be co-held at the stage.